|

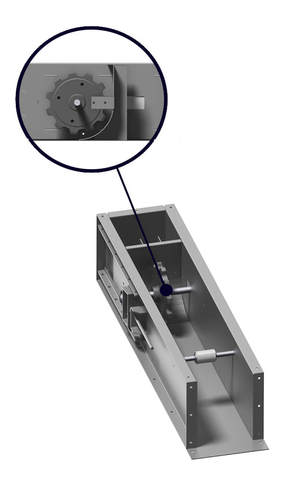

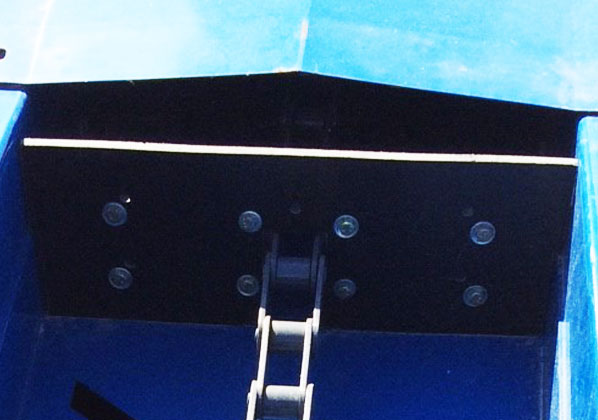

Protecting product from cross-contamination is critical, especially when it comes to seed and pulse crops. Your conveyance is where the risk for contamination is usually at its highest. This necessitates constant clean-out measures that take up valuable time and are less than cost-effective. Here at Norstar, we believe that chain conveyance provides a well-balanced solution to the issue of cross-contamination and here’s why… A Self Cleaning Conveyor Cleaning out your conveyors is an often frustrating and time-consuming process. We designed our chain conveyors to minimize the amount of maintenance required. We did this in a number of ways.

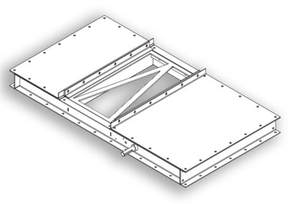

Fully Enclosed Protection Norstar Chain Conveyors feature a fully-enclosed conveyor housing that effectively seals off the product from external elements. Our conveyor covers are bolted on and we utilize UHMW seals at the shafts to ensure moisture and dust do not make contact with the material being handled. A fully-enclosed conveyor housing negates the need for external dust control measures, keeping your site clean and prevent further contamination risk to other products within the area.

Conclusion

Keeping your product clean and pure is a key ingredient to your success. That is why we spend so much time figuring out how to best design a conveyor that better protects you from cross-contamination and that minimizes your clean-out maintenance. Your comment will be posted after it is approved.

Leave a Reply. |

Archives

April 2020

CategoriesCOMING EVENTSGEAPS

Minneapolis, MN Date: March 21-24 Booth #: 2325 |

RSS Feed

RSS Feed

7/31/2017

0 Comments